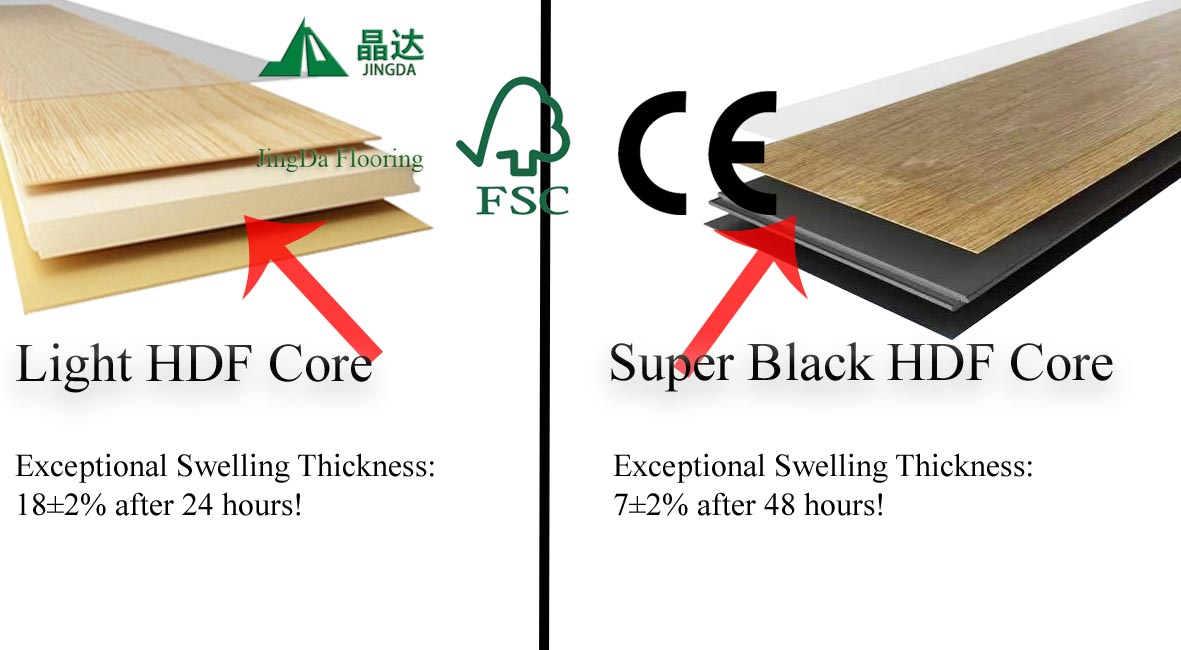

Jingda Hybrid Balck hdf core waterproof laminate flooring

Hybrid HDF Core Waterproof Laminate Flooring is a great promotion comparing with the traditional normal HDF Core Laminate Flooring.It behaves well in areas where there require better waterproof capacity of the flooring.

In the mean time,eco-friendly is another key factor people always pay attenttion to,and the formaldehyde free is especially taken into consideration for nearly every one before they start the decoration projects,no matter it is an office room,home ground,public commercial areas or other places might be.

You can always trust Jingda Laminate Flooring referring to the above mentioned key points. Jingda Laminate Flooring has achieved the certificates of CE/FSC,and all indices are qualified according to SGS reports. The hdf core board meets the CARB2 standrads,which is a graet guarantee for you breathing spaces.

Jingda hybrid hdf laminate flooring collections cover the normal thickness of 8mm,10mm and 12mm.

| SPECIFICATIONS LAMINATE FLOORING | ||||

| Product Name | Laminate Flooring | Laminated Floor | Pisos laminados | | |||

| Top Surface | Decorative film protected by Aluminium Oxide super wear and scratch resistance overlay | |||

| Bottom Surface | Balancing Film | |||

| Thickness | 8mm 10mm 12mm | |||

| Normal Size | 1220*127mm|1220*150mm|1220*170mm|1218*198mm |1220*200mm|1220*240mm|1220*300mm|1220*400mm|606*101mm|600*100mm|806*403mm|810*150mm 1515*200mm|1515*240mm|2440*240mm|2440*300mm | |||

| Surface Effects | Flat|Embossed|EIR(Embossed in Register) | |||

| Wear Resistance | AC3 AC4 AC5 AC6 | |||

| Laminate Flooring Pattern | Normal plank laminate flooring | Herringbone laminate flooring | Parquet Laminate Flooring | |||

| Installation Method | Licensed Valinge Click Connection/Double Click/Single Click/Arc Click | |||

| Warranty | 30 years Domestic 15 years Commercial | |||

| Technical Data Sheet | ||||

| Test | Standards | CHARACTERISTICS/ RESULTS | ||

| Behavior to impact load | EN13329 | IC 2 - height of fall 1700mm is the maximum height without damage (1750mm height) | ||

| Behavior to abrasion | EN13329 | IP 6000 Revolutions | ||

| Behavior to scratching | IS0 1518 | >25N | ||

| Insensitivity of wear layer to stains | EN 438.2.15 | Rating 5 (no effect) | ||

| Porosity | Graphite test 1 | Grade 1 (Pore-free) | ||

| Light fastness and fade resistance | EN 438.2.6 | Level 6 - Blue wool standard (No change /discolouration) | ||

| Cigarette test | EN 438.2.18 | Degree 5 = No visible change | ||

| Formaldehyde emission | E.T.B. Regulation | Approved and test at quality E1 | ||

| Waste disposal | N/A | Disposable with domestic waste. No Toxic fumes released during thermal disposal. | ||

| Fire classifcation | DIN 4102 | Flame-retardant-B1 | ||

| Ignitability | DIN 51960 | Does not ignite easily | ||

| Smoke development | 0-Norm B3800/1 | Class Q1- Low smoke development| (Austrian Institute for floor covering) | ||

| Indentation test | DIN 51955 | Residual indentation 0.0 mm(l.B.A- Koblenz). | ||

| Chair castor test | DIN 54324 | No negative changes when using soft wheel castors|According to Type W (l.B.A. Koblenz) | ||

| Susceptibility to cracking | EN 438-2.26 | No cracks observable. Subjected to large temperature change | ||

| Simulated pushing of furniture leg | EN 424 | No visible damage. | ||

| Thickness swelling test | EN 13329 | ≤ 5% swelling rate of a total board immersion after 24 hours | ||

| Joint strength | 1S0 24334 | fmax =4.25kn/m | ||