Stop Debating LVP or Laminate and Source Both Confidently

Global buyers frequently circle the same debate: LVP vs SPC comparison versus the evolving "waterproof" laminate sector. From a practical sourcing perspective, the smartest strategy is often not picking a single winner, but rather building a coordinated specification. This involves utilizing SPC flooring for true wet zones and leveraging waterproof laminate flooring China options for design-driven dry areas.

As a dedicated manufacturer in China producing both waterproof vinyl plank China products (SPC/LVP) and waterproof laminate, we see projects run significantly smoother when SKUs are aligned. By managing color, gloss, bevel, and packaging under one consolidated quotation, sampling, and QC plan, we ensure consistency. This integrated approach is why savvy buyers often shortlist a Laminate Flooring Chinese Factory that can operate alongside a SPC Flooring Chinese Factory under the same procurement playbook.

Understanding the Core Differences: LVP, SPC, and Waterproof Laminate

LVP (Luxury Vinyl Plank)

LVP is a flexible vinyl plank constructed around a PVC-based core.

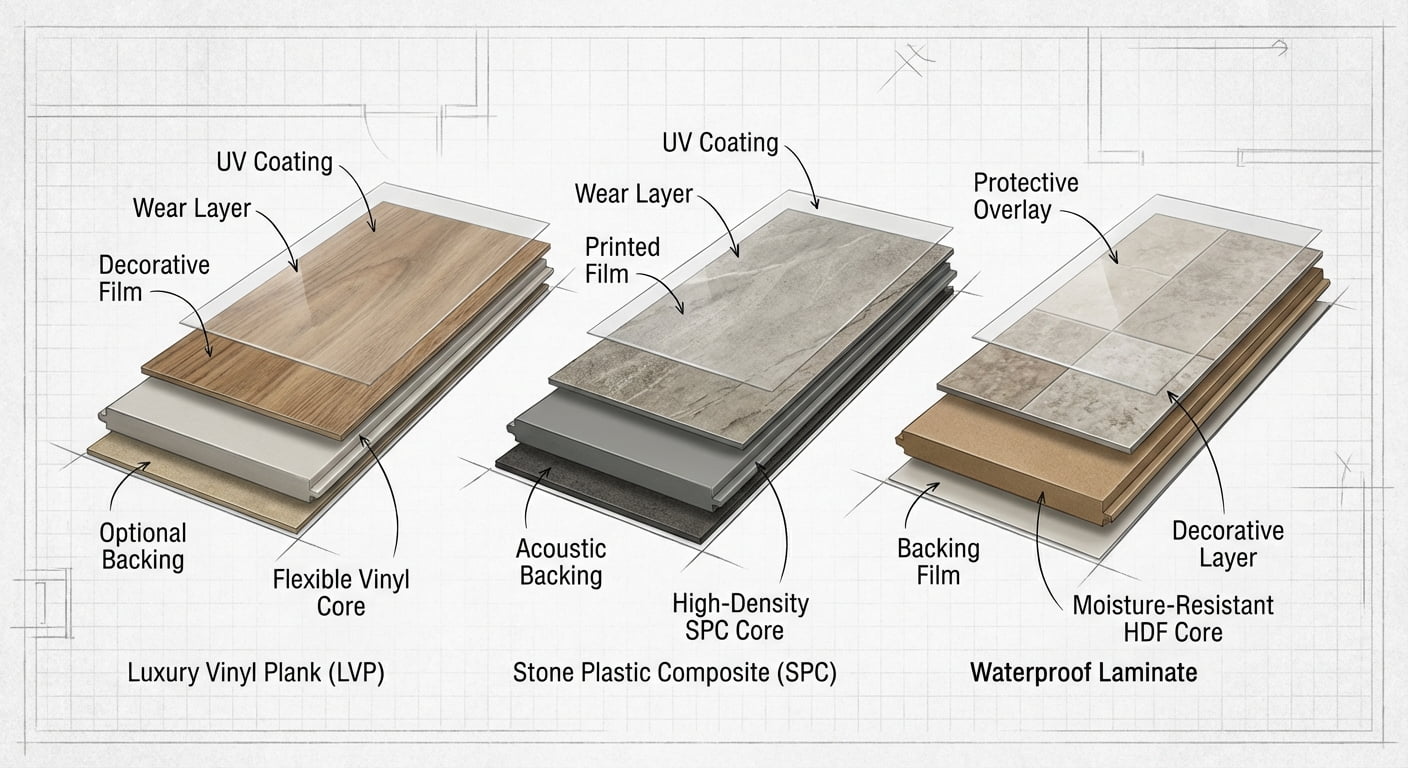

Typical build:

- Protection: UV coating + wear layer (0.3–0.7 mm)

- Visuals: Printed decorative film

- Structure: Flexible vinyl core

- Backing: Optional backing (commonly IXPE/EVA)

Most LVP ranges from 4–6 mm in thickness; however, thicker builds (up to ~8 mm) are often selected for enhanced comfort and sound control.

SPC (Stone Plastic Composite)

SPC is a rigid vinyl plank fortified with mineral fillers (commonly calcium carbonate) to ensure superior stability.

Typical build:

- Protection: UV coating + wear layer (0.3–0.7 mm)

- Visuals: Printed film

- Structure: High-density SPC core

- Backing: Optional acoustic backing

Many SPC flooring manufacturers China supply click-lock formats, allowing for rapid floating installation and robust water resistance.

Waterproof Laminate

Waterproof laminate retains an HDF core but significantly improves water performance through advanced substrate selection and joint protection.

Key elements:

- Moisture-resistant HDF

- Edge sealing + tighter locking geometry

- Improved overlay and backing films

Typical thickness falls between 7–12 mm. Performance is usually evaluated via AC ratings (AC3–AC5) rather than the vinyl wear-layer thickness used for LVP/SPC.

Comparison: LVP vs SPC vs Waterproof Laminate

When buyers compare waterproof laminate flooring China offers with SPC and LVP, four critical decision points emerge from real-world claims and callbacks: water exposure, stability, surface durability, and emissions documentation.

| Metric | SPC | LVP | Waterproof Laminate |

|---|---|---|---|

| Plank Waterproofing | Fully waterproof | Fully waterproof | Water-resistant; HDF-based |

| Dimensional Stability | Excellent | Good | Good with correct installation |

| Underfoot Feel | Firm | Softer | Solid, “woodier” |

| Common Thickness | 4–7 mm | 4–8 mm | 7–12 mm |

| Typical Fit | Wet areas + heavy traffic | Residential + renovation | Design-driven dry to moderate-moisture |

Pro Tip: For vinyl, strictly define the wear layer (0.3/0.5/0.7 mm). For laminate, define the AC class and request the matching test basis (e.g., EN 13329 or equivalent market requirement).

Where Each Product Performs Best

Instead of asking “which is best,” we recommend matching the material to the room’s specific risk profile.

Choose SPC when moisture and movement are the problem

- Locations: Bathrooms, kitchens, laundries, basements.

- Commercial: Rentals and commercial corridors.

- Condition: Subfloors that are not perfectly flat (SPC’s rigidity helps bridge minor imperfections).

Choose LVP when comfort and acoustics matter

- Locations: Living rooms and bedrooms.

- Application: Renovations needing easy height transitions.

- Priority: Projects prioritizing softer footfall and quieter steps.

Choose waterproof laminate when the design brief leads

- Locations: Living areas, offices, and showrooms desiring a more wood-like step feel.

- Preference: Thicker plank preference (often 10–12 mm).

- Environment: Moderate-moisture spaces where spills happen but standing water is limited.

A simple sourcing rule:

- Frequent water exposure → Go with SPC/LVP.

- Dry areas with premium look-and-feel → Go with Waterproof Laminate.

- Mixed-use buildings → Combine both under one aligned finish and packaging plan.

Critical Questions for Your Chinese Factory

The fastest way to reduce quote gaps between Laminate Flooring Chinese suppliers and SPC Flooring Chinese suppliers is to make your RFQ (Request for Quotation) measurable.

RFQ Essentials (Copy/Paste into your inquiry)

- Product Type: SPC, LVP, or Waterproof Laminate.

- Thickness: Total thickness + tolerance.

- Surface Durability: Wear layer (vinyl) or AC rating (laminate).

- Plank Size & Bevel: Micro-bevel or square edge.

- Locking System: Type and profile expectation.

- Underlay: With/without IXPE/EVA, specific thickness.

- Finish: Texture/embossing, gloss range, color targets.

- Packaging: Pcs/carton, m²/carton, pallet limits, barcode + label language.

Sample-Stage Tests to Prevent Surprises

Ask for factory results and, when needed, third-party confirmation:

- 24–72 h Water-Soak: Including edge soak and joint swelling observation.

- Abrasion Verification: Taber test or AC class confirmation.

- Click-Lock Strength: Fit consistency and tensile strength.

- Static Indentation: Resistance to furniture load.

- Safety: VOC/formaldehyde documentation for your destination market.

This is where a Waterproof Laminate Flooring Chinese Factory can demonstrate edge protection consistency, and a SPC Flooring Chinese Factory can showcase profile precision and core density stability.

OEM Branding and Supply Chain Advantages

Most professional Waterproof Laminate Flooring Chinese suppliers and vinyl producers support OEM details that buyers often overlook until it’s too late:

- Private-Label Cartons: Custom SKU naming, barcodes, and multilingual labels.

- Documentation: Installation guides and warranty leaflets.

- Logistics: Project pallet plans and mixed-container loading.

- Design: Décor coordination across SPC/LVP and laminate collections (volume-dependent).

To avoid rework, share your artwork (AI/PDF) and label text at the quotation stage. It remains the simplest way to keep lead times and landed costs predictable.

Next Steps for Your Project

If you are building a product line or bidding on a project, we recommend specifying both: choose SPC or LVP for wet zones, and use waterproof laminate where the aesthetic and thicker feel are the priority. This blended approach consistently reduces risk while keeping the catalog cohesive.

Contact us to request samples, technical data sheets, and a quotation aligned to your target market and installation conditions.