Water Resistant Laminate

One home decorating option that seamlessly blends aesthetic appeal and versatility with remarkable affordability is water resistant laminate wood flooring. This visually appealing and sophisticated choice in decorative flooring offers an optimal balance, enabling even budget-conscious individuals to achieve the desired look and ambiance for their spaces. Ranging from rustic to refined, the extensive array of styles available makes this flooring one of the most adaptable options on the market today. In fact, high quality waterproof click lock laminate flooring delivers a visual allure, tactile experience, character, and charm that can rival its more luxurious—and significantly pricier—counterparts such as hardwood, marble, and stone.

Looking for flooring that delivers the warm look of hardwood but holds up to daily splashes, spills, and accidents? Say hello to water resistant laminate—a modern flooring solution that blends beauty, budget-friendliness, and day-to-day durability. Whether you're remodeling your home or updating a rental property, water resistant laminate offers an ideal balance of aesthetics and resilience.

In this guide, we’ll explore what makes water resistant laminate a game-changer, where to use it, and how to make the right choice for your space.

🔍 What Is Water Resistant Laminate?

Water resistant laminate is a type of engineered flooring composed of several layers, including a tough wear layer, a realistic decorative layer, and a dense core. What sets it apart from traditional laminate is its ability to repel moisture, giving you a longer window to clean up spills before they cause damage.

🛡️ It’s not fully waterproof like SPC or vinyl, but water resistant laminate provides ample protection for daily life scenarios—think pet water bowls, kitchen mishaps, or muddy shoes at the front door.

💡 Key Benefits of Water Resistant Laminate Flooring

✅ Moisture Protection Where You Need It

Unlike standard laminate, water resistant laminate can handle occasional water contact, making it perfect for kitchens, hallways, and entryways.

✅ Hardwood Looks at a Fraction of the Price

Thanks to high-resolution printing and embossing, modern water resistant laminate can mimic oak, maple, walnut, or even stone—often fooling the eye even up close.

✅ Durable for Busy Households

With its wear-resistant surface, it stands up to scratches, dents, and foot traffic—ideal for kids, pets, and daily life.

✅ DIY Installation

Most water resistant laminate comes with a click-lock system, so you can skip the professional installer and save on labor costs.

✅ Easy Maintenance

Just a quick vacuum and damp mop are enough to keep it looking brand new—no waxing, sanding, or sealing required.

🏠 Best Places to Use Water Resistant Laminate

While not suited for constantly wet areas like shower rooms or saunas, water resistant laminate flooring is fantastic for:

✅ Kitchens

✅ Hallways and foyers

✅ Living rooms

✅ Dining areas

✅ Bedrooms

✅ Home offices

✅ Laundry rooms (with proper care)

💬 Real User Reviews

@HomeWithJade

“We installed water resistant laminate in our kitchen and hallway 6 months ago. The kids spill juice constantly, but the floor still looks amazing. Highly recommend!”

@DIYDadMike

“I laid water resistant laminate myself—took me two days, no glue or nails. The finish looks like real oak and handles our dog's messes like a champ.”

@RentalProErika

“I manage multiple rental units, and water resistant laminate has been a go-to. Tenants love the look, and I love the price and durability.”

🛒 What to Consider When Choosing Water Resistant Laminate

Before buying, ask yourself:

AC Rating: Higher AC ratings (AC4 or AC5) mean better durability

Core Type: High-density fiberboard (HDF) offers better moisture resistance than MDF

Edge Sealing: Beveled and wax-sealed edges add extra spill protection

Wear Layer Thickness: Aim for 10mm–12mm for comfort and stability

Warranty: Look for at least 15-25 years residential coverage

Certifications: Choose FloorScore® or CARB Phase 2 certified for indoor air safety

Always order samples and test them under your home’s lighting and moisture levels before finalizing.

📈 Water Resistant Laminate vs Other Flooring Types

| Feature | Water Resistant Laminate | Standard Laminate | Vinyl Plank | Hardwood |

|---|---|---|---|---|

| Moisture Resistance | ✅ Moderate to High | ❌ Low | ✅ Excellent | ❌ Low |

| Realistic Appearance | ✅ Very High | ✅ Good | ✅ Good | ✅ Natural |

| Scratch & Dent Resistance | ✅ Strong | ✅ Strong | ✅ Strong | ❌ Moderate |

| Price | ✅ Affordable | ✅ Budget | ✅ Budget | ❌ Expensive |

| DIY Installation | ✅ Click-Lock | ✅ Click-Lock | ✅ Click-Lock | ❌ No |

| Maintenance | ✅ Low Effort | ✅ Low Effort | ✅ Low Effort | ❌ High |

🧠 Final Thoughts: Is Water Resistant Laminate Worth It?

Absolutely. If you want the high-end look of hardwood, but need a floor that can survive real-life chaos—water resistant laminate is a smart, stylish, and affordable solution. It offers the charm of wood without the high cost or vulnerability, making it ideal for active families, pet owners, and rental property managers alike.

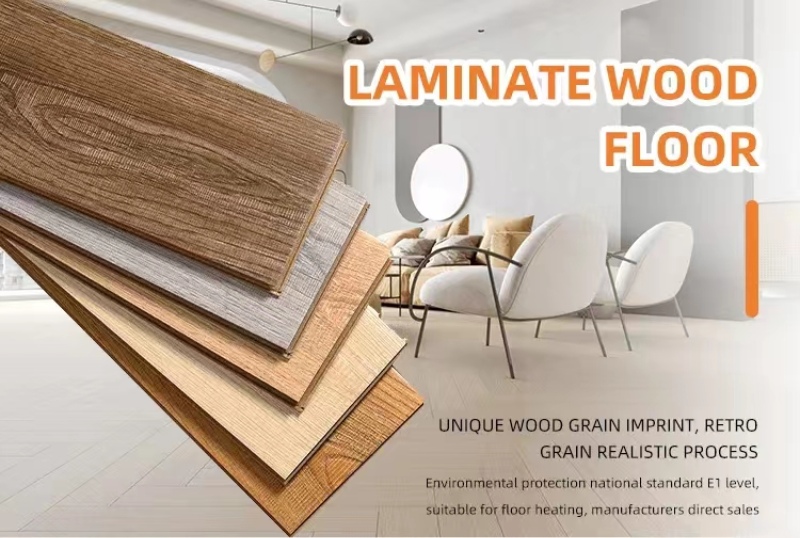

Product Parameters

| Product Name | Laminate Flooring | ||

| Wear layer | AC1(Class 21),AC2(Class 22), AC3(Class 31),AC4(Class 32), AC5(Class 33) | ||

| Base board | MDF, HDF, Based board density 700/ 730/ 810/ 830/ 850 kg/m3 or customizable | ||

| Balance paper | Color: Brown, Green,Yellow,Blue | ||

| Surface | Mirror or Piano,High gloss,Matte,Small embossed,Middle embossed,Big embossed,Crystal,EIR, Real wood, Hand scraped | ||

| Regular dimension | 606x101mm, 806x403mm, 810x150mm, 1218x198mm, 1220x127mm, 1220x150mm, 1220x170mm, 1220x200mm, 1220x400mm, 1515x200mm, 1515x240mm, 2400x240mm, 2400x300mm | ||

| Thickness | 7mm, 8mm, 10mm, 12mm | ||

| Thickness swelling rate | <18% or customizable | ||

| Formaldehyde emission | E0, Carb P2, E1 | ||

| Floor edge | Square edge, V-groove, U-groove | ||

| Click Lock | Single click, Double click,Arc,Valinge,Unilin | ||

Product Structure

1. Excellent Wear-Resistant Performance

Aluminium trioxide component similar hardness to diamond, no maintenance cost.

2. Delicate Surface Technology

3D Embossing process,realistic feeling of natural wood grain

3. High-Density Fiber Board

High-density, high-strength, E1 Class of environment-friendly.

4. Moisture-proof Balance Layer

Dampness isolation, no mildew, no deformation.

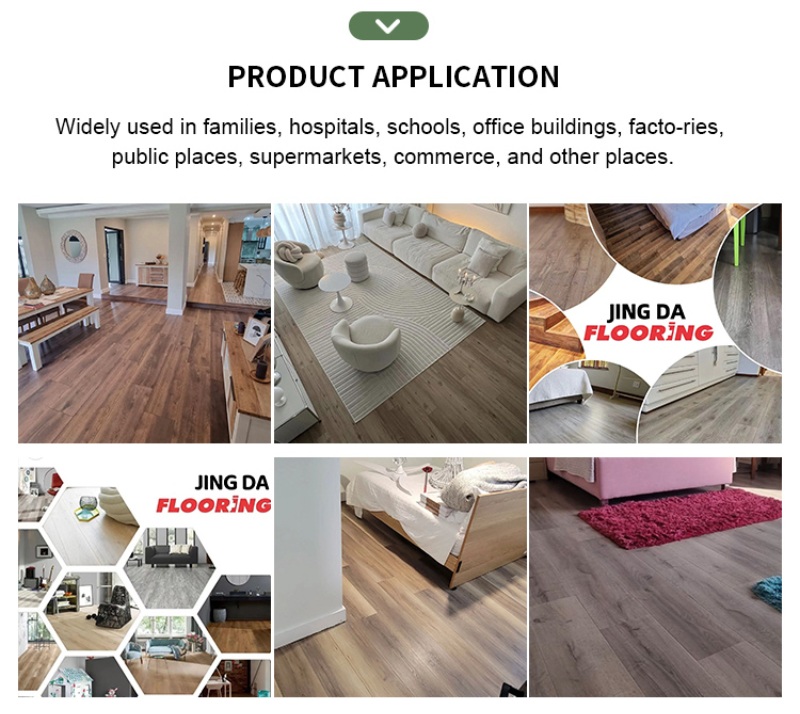

Product Application

The laminate floorings are widely used in families, hospitals, schools, office buildings, factories,public places, supermarkets, commerce buildings, and other places.

Production Process

1. Hot Pressing: Arrange the balance paper, substrate, and decorative paper in order, then subject them to high temperature and pressure during the pressing process. For U-groove laminate flooring, a two-step pressing is required; first, press the balance paper and substrate together, followed by an additional press with the decorative paper. After hot pressing, allow the laminate flooring to release for 1-2 days.

2. Cutting: Divide the large laminate sheets into smaller pieces of uniform size by initially trimming the short sides before cutting them into small boards while also trimming the long sides.

3. Released: Following cutting, further curing of the laminate flooring is necessary; this stage typically lasts between 2-6 days.

4. Slotting: The slotting process involves creating chamfers—first on the long side and subsequently on the short side. Once slotting is complete, apply paint to the planks.

After painting, drying is essential before sealing wax onto all four edges to enhance water resistance.

5. Packaging: The final step involves packaging; place the laminate flooring in a cardboard box which can be either half-box or full-box packaged before arranging it in bulk or on pallets.

Submitted successfully

We will contact you as soon as possible